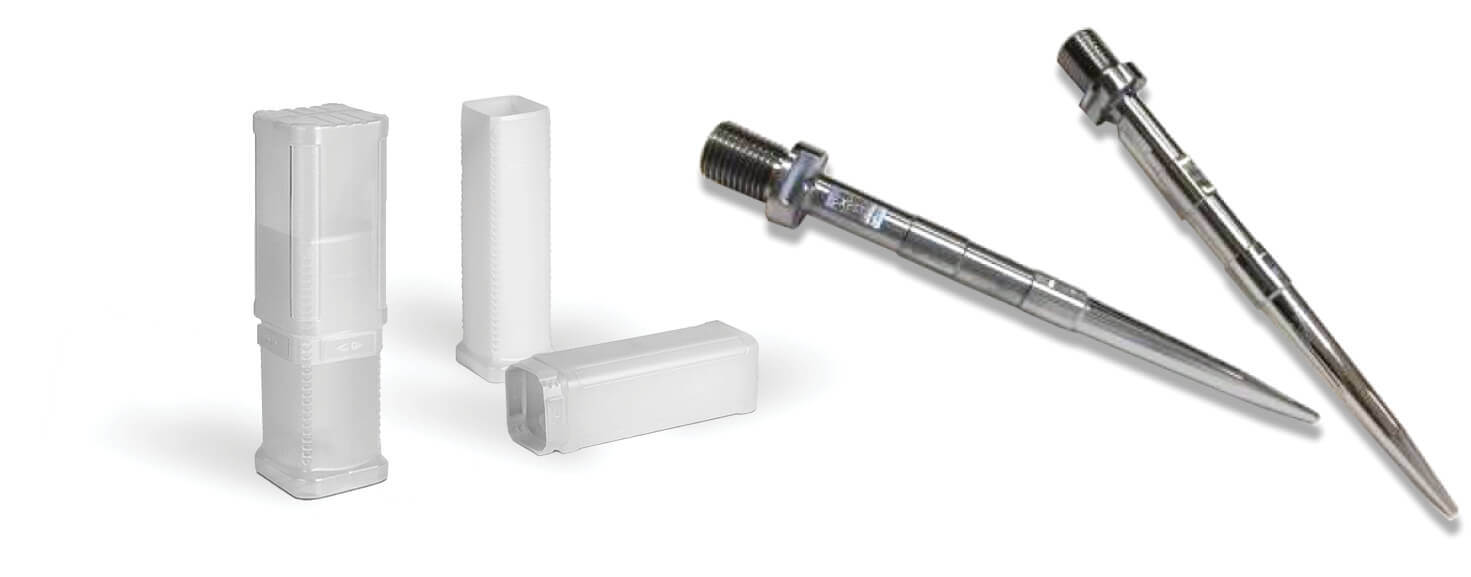

Core Pins & Sub Inserts

Guaranteed Performance, One step ahead

High Performance Core Pins & Sub Inserts for Die Casting Application

Our Tailor made High Performance core pins and sub inserts for high pressure die casting applications are made of Böhler W360 ISOBLOC, a unique material specially designed and manufactured for such high demand application by Böhler Austria with High performance Vacuum Heat Treatment and PVD Coating.

Advantages

• Much longer life than “standard” core pins

• Higher hardness (up to 57 HRC)

• Higher toughness/ductility

• Improved thermal conductivity

• Improved wear resistance

• Reduced soldering

Our high performance core pins and sub inserts are being coated with DUPLEX-TIGRAL® PVD Coating which is the proven solution in high pressure die casting industry worldwide. Due to the unique characteristics of Böhler W360 ISOBLOC our High Performance core pins and sub inserts can achieve an out-standing hardness level with much better toughness than the normal H13.