Additive Manufacturing is the Revolution in Manufaturing Technology

Especially in this promising segment, BOHLER India can build on its extensive materials experience and expertise in the field of powder metallurgy. We are expanding our portfolio to include powder for additive manufacturing with the brand BOHLER AMPO, starting April 2017.

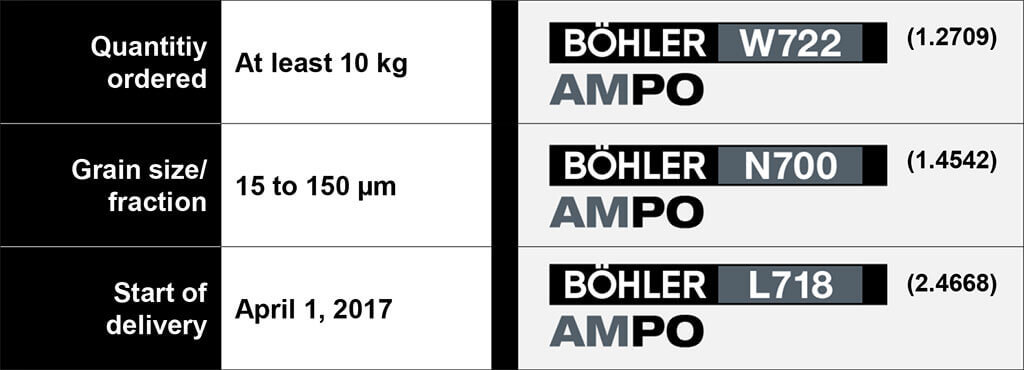

The facts at a glance:

- Launch with 3 brands – BÖHLER W722 AMPO, BÖHLER N700 AMPO, BÖHLER L718 AMPO – but great flexibility to expand the brand portfolio in the future.

- Atomization of BÖHLER standard brands (theoretical selection from 250 steel brands). Customization of alloys with small scale production plant and metallurgical expertise.

- BÖHLER India leverages the metallurgical knowledge and manufacturing options of a special steel producer for this new technology.

- Powder is produced on latest atomization techniques and tested in-house.

- Vacuum induction melting and atomization under inert gas ensure the highest product quality.

- Depending on the steel grade and customer requirements, raw-materials molten under vacuum or remolten can be used. This ensures the highest quality standards and minimizes undesired impurities.

- Depending on the requirements of the AM process used, we can provide the appropriate particle fraction in a range from 15-150μm.

- Properties such as flowability, particle size distribution, and bulk density are ascertained upon request and included in delivery.